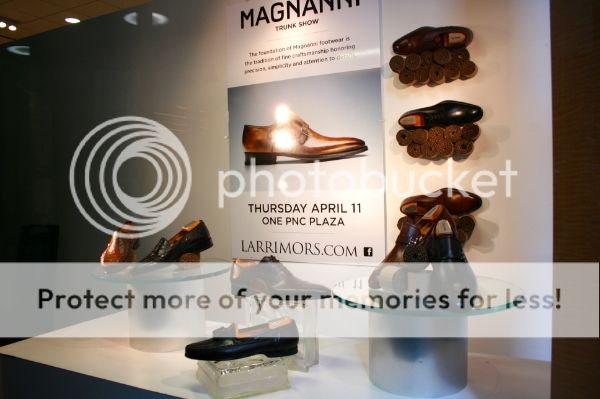

Larrimor’s is having a Magnanni Trunk Show on Thursday, April 11th, at One PNC.

Magnanni is a third generation family business. I caught up with the U.S. Director Pascual Blanco (who also happens to be the grandson of founder Sebastián Blanco Aldomar) to ask a few questions about the brand.

Why do you think that the family tradition is such an important aspect of the Magnanni brand?

Now a days most companies do not own their factories. They own the brands and use factories around the world to make their products. Our family tradition and the know how is necessary for our survival in this competitive world. Our brand is not as important or well-known as other international brands, but customers recognize the quality and value of our product. We are able to compete with the mega brands by offering same or better quality products at a greater value, and this is only possible when you can design, manufacture, and distribute your own product. Our family controls these 3 important points and this is why we can be competitive.

Your grandfather started in the business at age twelve and your father at fourteen. When did you start helping out? What are your earliest memories of working at the company?

Things have changed a lot. My grandfather and father started working at a young age because of a necessity. Growing up, my brothers and I spent a lot of time in the factory during the summer. My father and mother wanted us to respect the workers and understand what it takes to manufacture shoes. Working in the factory helped us understand better our workers’ positions as well as develop relationships with them that no other owners have. We used to help with jobs that did not require high skills. Most of the processes of the shoe production are very difficult, so you need have the skills to be able to do the job correctly. We used to help in the factory packing shoes, mating samples, lacing shoes,… mostly non-skill jobs. Most importantly, it helped us to understand the business and build relationships with our workforce.

You manage to keep your shoes at a reasonable price point for their quality. How is this possible?

As I explained before, it is part of building a structure that is efficient and direct. We try to keep expenses down by designing, manufacturing and distributing the products ourselves. By doing this, we can offer to our customers a great quality product at a great price. The most important thing is that our family controls these three important points:

My brother Sebastian oversees the company.

My brother Luis is the Designer and controls the Design team.

My brothers Julio and Miguel control the buying department as well as the manufacturing.

My sister Rocio is in Sales in Europe.

I control company and sales in USA and Asia.

When someone hears “made-to-measure” they don’t usually think of shoes. Tell me more about this process and also Magnanni’s hand finishing.

Made to measure in shoes is very complicated. When you make a suit or a shirt made to measure you can make changes and stich and un-stitched the product. On a shoes, if the shoe does not fit, you need to start again and make a new shoe. So it is very challenging.

What Magnanni is well-known for is the unique finishing and coloration of our products. We create our own colors as well as finishes. So we decided offer to our customers the possibility of making a shoe in any color and any fished they like. So we bring to the store a made shoe but in raw leather. Picture a white canvas but on a shoe. Then, after speaking with the customer and listening to his request my brother Miguel starts painting the shoe. It takes around 3 hours to paint a pair of shoes. It really is a piece of art. We do this at events all around the world and in the best stores.

Magnanni rests on tradition. I’ve been on your Facebook page. I saw the steps to making a shoe on Instagram. How is the company moving forward and changing to keep up with the digital world?

We do spend a lot money and time in adding new technology into our company. We believe that if technology is used correctly it will improve productivity but we also believe the importance of tradition. It is a combination of both what we feel is the best for our company. Shoe making is a very labor intense process with a need of very precise skills. We cannot change that but technology is helping us make a better product and more efficient. Design is almost all done with computer systems. A lot of the cutting is done with sophisticated machines that not only cut the leather perfectly but that maximize it. The whole factory is set up with barcodes allowing us to know where each shoe is in each process of the production. There are really many ways that we can use the digital world into our advantage but the hands of a skill artisan are impossible to replace.